Are you making holes in stacked truck frames?

Installing new accessories or a new axle can be difficult. It takes time to properly align and drill the holes, not to mention the challenges.

Are you still drilling with twist bits?

Challenges with twist bits:

- Need to drill pilot hole for larger holes

- Inaccurate and oval hole shape

- Takes a long time to drill through

- Constantly re-sharpening due to hard material

There is a faster and more precise way of drilling frames.

A magnetic drill with an annular cutter only cuts the outside of the hole.

Annular cutter advantages

- More holes per bit

- Cuts about 4 times faster

- Reduced risk of drill tilting

- Perfectly round hole

Or are you using a mag drill with annular cutters?

Challenges with typical annular cutters

- Cutters often break during the drilling

- Slug always needs to be removed before drilling the second hole

- Drill needs to be realigned with the hole before drilling the second layer

In the end, more time is spent repositioning the drill instead of actually drilling, not to mention repeatedly breaking annular cutters can get expensive quickly.

Have you ever timed your hole making process?

It is important to know exactly how long it takes for every operation, to understand where your bottleneck is and how you can improve it to be able to deliver trucks faster.

What if you could cut your hole making time in half?

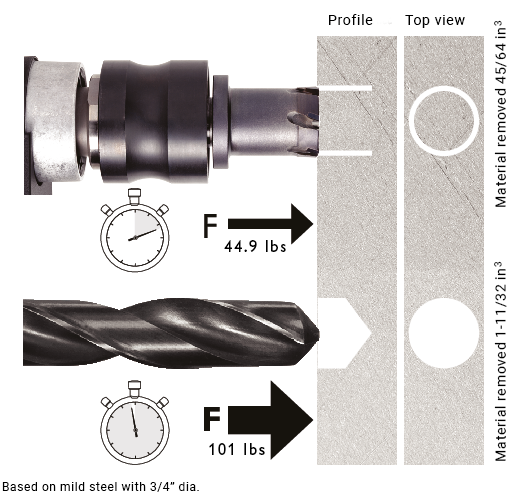

The secret is truck frame cutters (also called ID-style cutters) that are designed specifically to drill through multi-layers of steel, reducing the cost per installation. Carbide-tipped to handle the hardness of the frame, they reduce the drilling time with no need to remove the slug or reposition the drill between each stack.

What is so special about truck frame cutters?

Typical annular cutters have a geometry designed to cut through a single layer of metal producing a fast, clean hole with a single slug of material. The geometry leaves a lip at the end of the slug, which is the reason why you can’t drill both layers in one step.

Truck frame cutters have a different geometry that allows for drilling in harder material. No lip is left on the slug, which enables you to drill through both layers of the double frame in one simple step.

Truck frame cutters in action

JMC MAGFORCE 90

Smallest and lightest magnetic base drill with forward/reverse operation on the market. Access hard-to-reach areas and easily work overhead or vertically.

To the productID Cut Truck Frame Cutters

¾” Weldon shank - 1” depth of cut

Item # Diameter

69908037333 9/16”

69908037334 5/8”

69908037335 11/16”

69908037336 3/4”

69908037337 13/16”

69908037338 7/8”

69908037339 15/16”

69908037340 1”

69908037341 1'/₁₆”

69908037342 1⅛”

69908037343 1³/₁₆”

69908037344 1¼”

69908037345 1⁵/₁₆”

69908037346 1⅜”

69908037331 Pin for diameters 9/16” to 11/16”

69908037332 Pin for diameters 3/4” to 1⅜”