Making holes in curved-shaped metals.

It's always been a challenge to make easy, burr-free, perfectly round holes on curved-shaped material while staying safe at the same time.

There are many different ways of solving this application, here are the most common ones.

Most common method to drill in curved-shaped materials.

HAND DRILLS

| PROS | CONS |

|

|

PLASMA CUTTERS

| PROS | CONS |

|

|

MAG DRILLS WITH ANNULAR CUTTER

| PROS | CONS |

|

|

Our recommendation

To overcome these obstacles and make the perfect hole, we recommend using the FEIN KBH 25-2 U. It offers most of the upsides of the previously mentioned methods, without the downsides. Because this is an hand-held tool, the type and shape of the material doesn't matter. With this technique you can also drill trough galvanized pipes because the coating don't affect carbide cutters. Plus, the unique pilot pin combined with an annular cutter allows for drilling with ease through curved material, weather it's an inside or outside radius. Get the most out of your tool with the FEIN wHole solution.

Drilling in curved material

If you think this tool is like the drill you own, STOP! You have it all wrong.

Three reasons why this tool is on a totally different level.

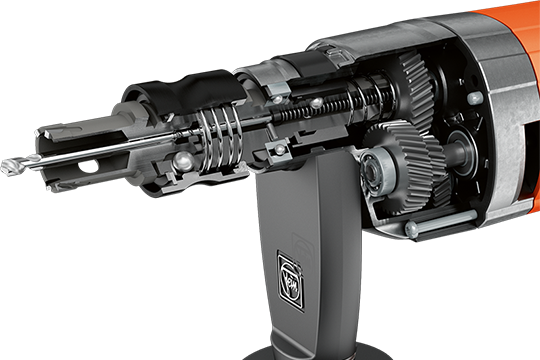

Higher safety level

The mechanical 2-speed gear box is built

with a torque slip clutch designed to drill in metal and protect the operator against injuries to the wrists, arms or shoulder that can happen when a bit jams or binds up during operation.

Perfectly round and burr-free holes every time

Annular cutters allow you to quickly drill a perfectly round, high quality hole every time. Up to a 3/4" thick in any metal: steel, aluminum, stainless, cast iron, and more.

Flexibility in hole processing

Includes a tapping chuck and a 5/8" drill chuck to deal with the full range of drilling applications:

- Twist drilling

- Core drilling

- Hole sawing

- Tapping

- Countersinking