Mississauga, November 1st, 2019. FEIN adds a new model to its range of Slugger mag drills: the JMU137 PQW with ¾ in Weldon mount. Suitable for drilling holes with diameters of up to 1-3/8 in (35 mm) and cutting depths of up to 2 in (50 mm), the JMU137 PQW can be used for all drilling work: core drilling, twist drilling, tapping, countersinking and reaming. The speed can be slowed electronically up to 130 revolutions a minute in five steps.

High magnetic holding force ensures stability and safety

“In addition to flexible use, developers have made huge advances in tool safety,” explains product manager Christian Kreb: “Users, who have to continuously drill holes vertically or at height – be it in steel girders or overhead on bridges – require especially good occupational safety.” If someone disconnects the power source by mistake, the tool and its electric magnet might fall. This explains why FEIN has equipped the new core drills with a permanent magnet. “The magnetic holding force is guaranteed regardless of the power supply – primarily for user safety but also of course to protect the tool,” says Christian Kreb.

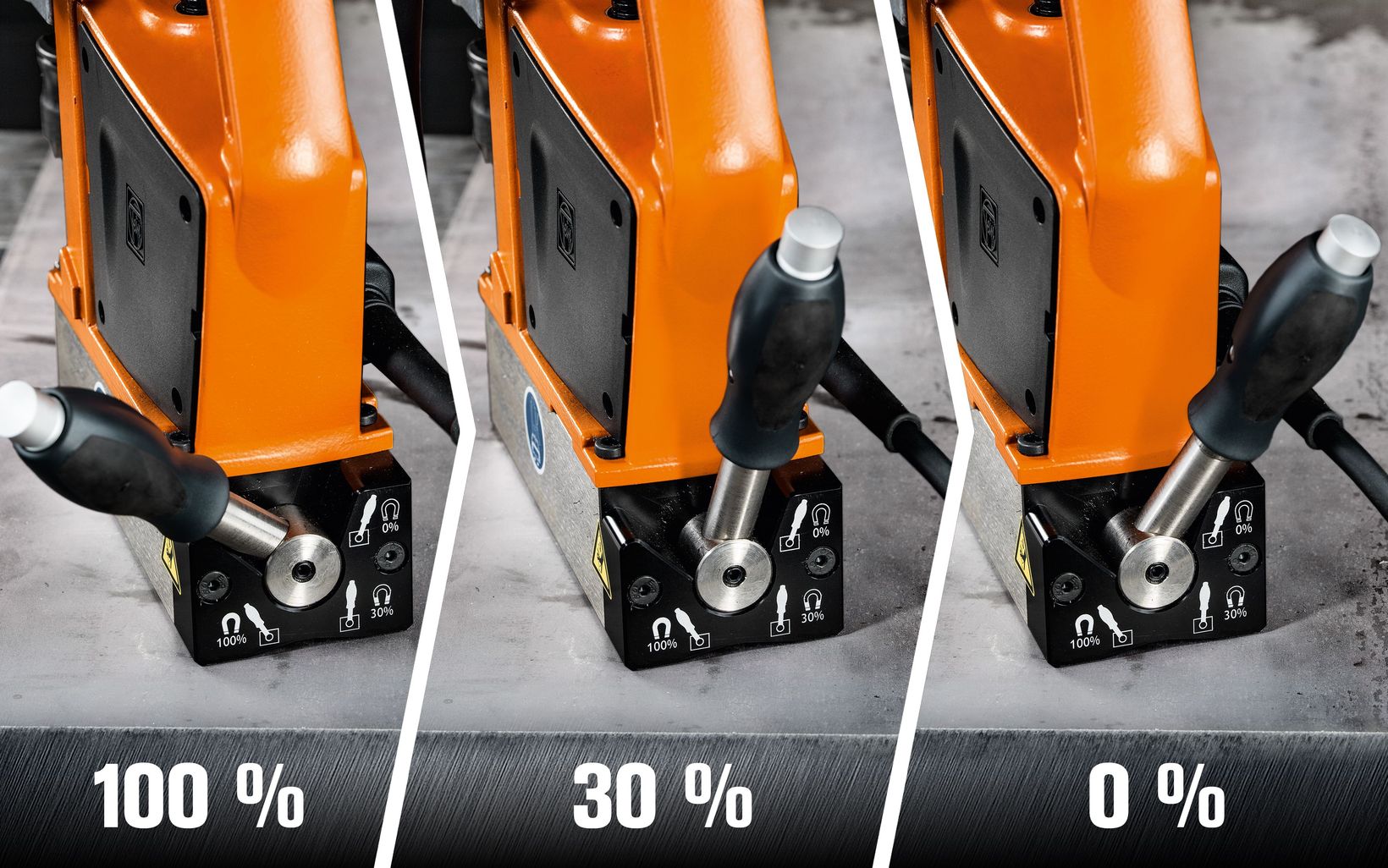

Users can manually bias the permanent magnet. In other words, they move the mechanical lever to 30 percent which enables the magnet to hold the weight of the tool. The next step is to position the tool on the workpiece, which may be overhead depending on the application. Then, they move to the drill point and use the mechanical lever to set the permanent magnet to 100 percent holding force. The tool can only be started once it is fully fixed into place.

Plenty of power and a huge stroke

The JMU137 PQW features a robust 1,010 W high-power motor. The integrated tacho- electronics help to stabilize speed under load. The tool-free adjustment of the motor, thanks to the drill motor clamping lever, can be used to extend or shorten the stroke range to suit the application. Both short and long drilling accessories can be used.

The new and powerful magnetic core drill has been designed to allow users to work with flexibility: for example, operators can use the tool-free FEIN quick-change system to change cutters with ease, and the weight of the tool at only 27.5 lbs (12.5 kg) allows for use in many different places. The feed handwheel can be positioned on the right or the left side of the tool and the swivel-mounted motor cable moves flexibly with the drill no matter how the tool is used.

Convenient magnetic holding force display helps achieve precision positioning

To align the tools with precision, the drill has an easily visible magnetic holding force display on the top of the drill motor. The self-explanatory controls are easy to use and resistant to dirt and dust. An integrated memory function saves the last set speed and allows it to be recalled as often as required for serial work. Once the tool is affixed to the workpiece with 100% holding force, the tool indicates this by means of a green permanent light. The light will start to flash if the holding force is impaired in any way. If the tool does tilt or slip, a tilt sensor on the drill motor stops the tool within seconds – another safety feature from FEIN.

FEIN range of mag drills in five performance classes

The demands that end users place on functionality, price and performance are just as varied as the applications that they have to cope with in their day-to-day work. FEIN has responded to this by offering five different performance classes: Mobile, Endurance, Compact, Universal and Automatic. The Mobile performance class includes the KBH hand-held drilling system for flexible hand-guided drilling. The Endurance class offers mag drills that provide basic functionality and are in the lower price range. The Compact class provides tools are optimized with respect to their size so that metalworkers can even use them in the girder web of a steel girder. Mag Drills in the Automatic performance class have a fully automatic drill feed to ensure efficient working. The JMU137 PQW single-speed universal mag drill belongs to the Universal class. Thanks to its broad range of functions, it can be used for a wide variety of applications. As with all FEIN products, users can also register the JMU137 PQW for the 3-year FEIN PLUS warranty.