You must work with great precision when machining pipes. Special serrated discs with a soft fleece lamella intermediate layer are available for such tasks. These elastic discs can also be held at a slight angle to the welded seam, which can be removed quickly at a maximum speed of 4,200 rpm without a facet forming on adjacent surfaces. For a satin grinding pattern, we would recommend using a grit 120 lamella flap wheel (speed: 2,500 to 2,800 rpm). The surface is then given the perfect end finish using a finishing disc at a speed of 3,500 rpm in the rotary procedure.

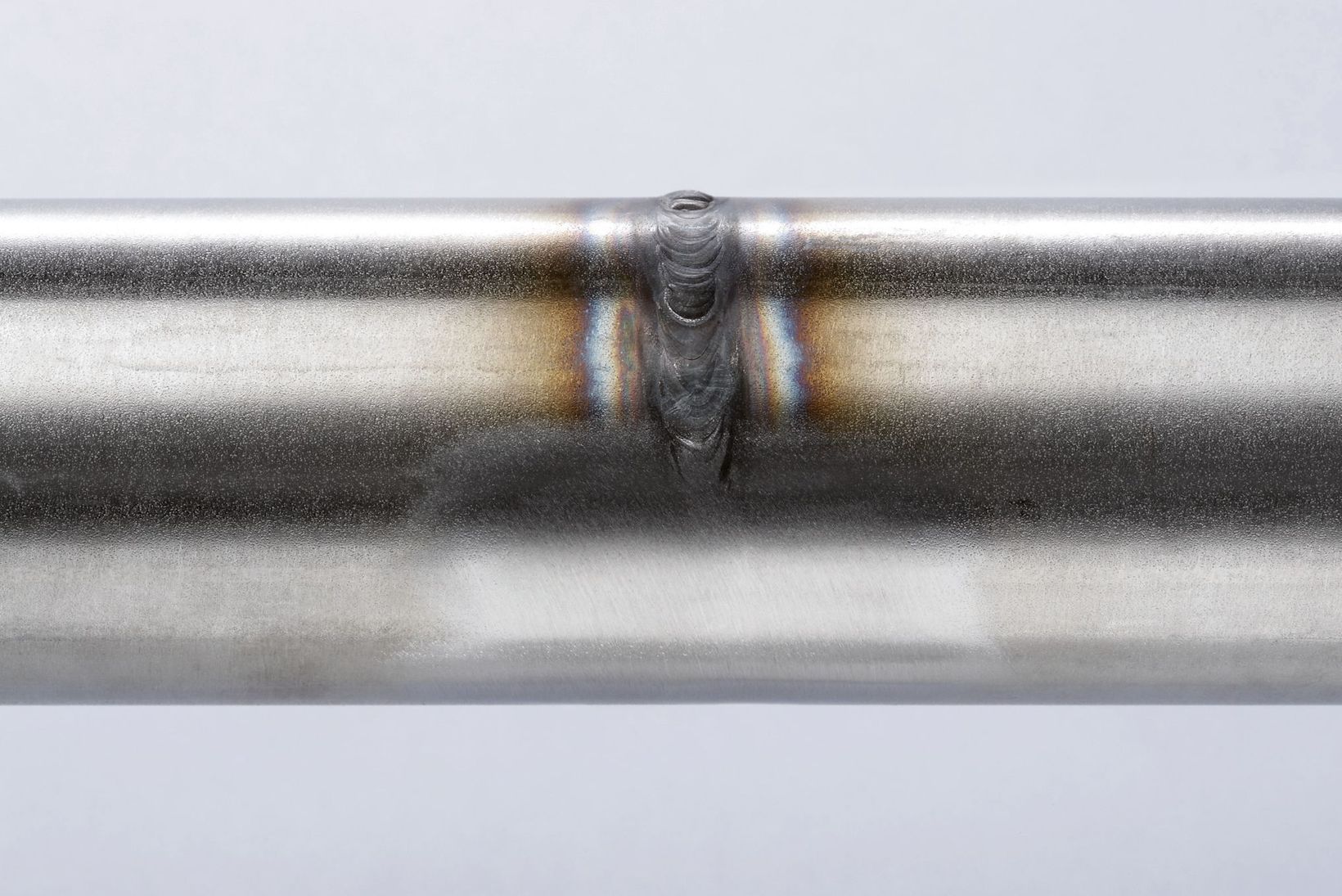

Welded seams are efficiently removed in the rotary procedure using an elastic serrated disc.

An elastic serrated disc ensures fast material removal and doesn’t damage the adjacent surfaces.

A lamella flap wheel ensures a satin grinding pattern.

A finishing disc achieves a perfect surface result.