The inventor Wilhelm Emil Fein

When Wilhelm Fein founded his ‘workshop for electrical and mechanical apparatus’ in 1867, electrical engineering was a new technology. Fein had great talent as both an inventor and an entrepreneur, and he came to be recognised as a pioneer of electrical engineering in his own lifetime. His richly inventive spirit provided the momentum for 150 years of company success and the ideas of the future.

Further development of a telephone with improved transmission quality

Just months after Bell’s telephone was introduced to the world, in 1877, FEIN launched a telephone with a horseshoe magnet – the new standard which was to remain in place for many years. In 1879 Wilhelm Emil Fein was awarded a patent for an improved telephone with better transmission quality. Telecommunication became an important line of business: FEIN built and installed telegraph and telephone systems, including systems that functioned as fire alarms. Between 1882 and 1885 FEIN built the public telephone network for the city of Barcelona, and in 1892 it was FEIN technology that made possible the first telegraphic opera broadcast, from the Stuttgart Opera to the royal Villa Berg.

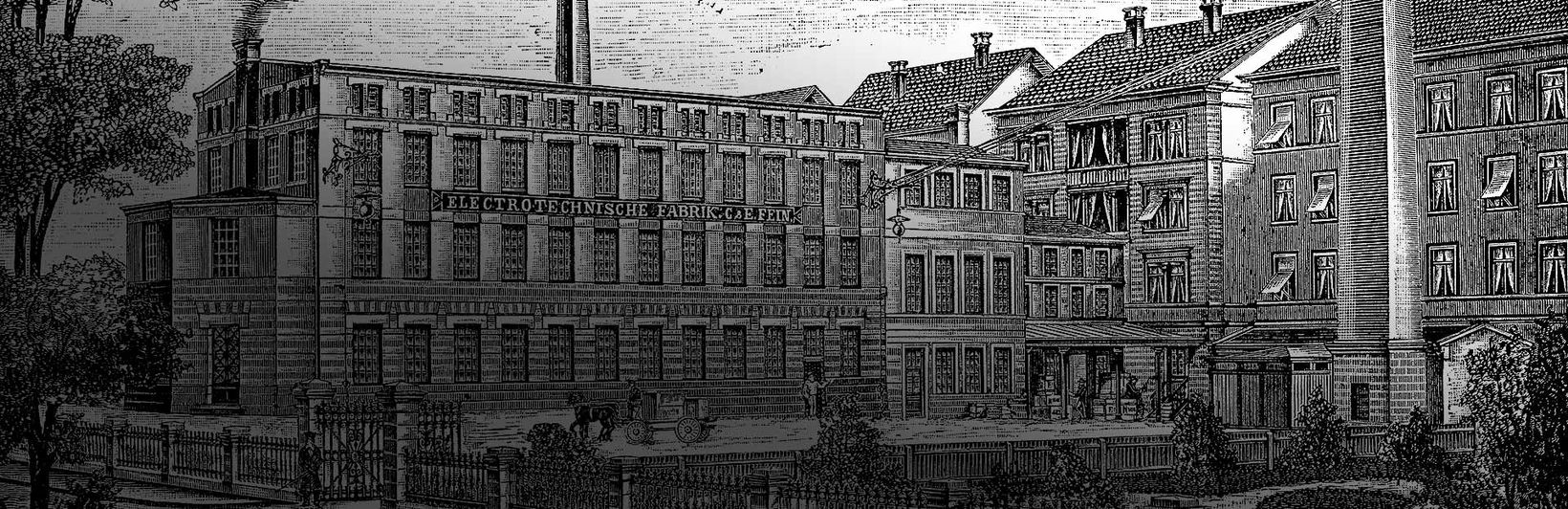

Foundationelectricalengineeringfactory

Electrical engineering factory of C. & E. Fein, Stuttgart

Electric hand drill

The next labour-saving invention was the world’s first power tool. In 1895, the resourceful employees at FEIN combined a hand drill with small electric motors. The concept of a tool with an individual electric power source was born. The first prototypes to use the now familiar ‘pistol’ shape were built in 1918 in accordance with an American model.

Exhibition

Exhibition of electrical engineering and applied arts, Stuttgart

Handheld sanding motor

FEIN was not slow to recognise the potential of the new hand-operated power tool. In 1908, FEIN became a 'specialised factory for power tools'. Initial efforts focused on quickly improving the drill, giving it more power and making it more lightweight. The next power tool to follow was the portable sanding machine.

FEIN hammer

The technology used in the first electric pneumatic hammer is still used today. All hammers have an air-cushioned striking mechanism. To develop the FEIN hammer, the rotating motion of the electric motor was successfully converted into a linear striking motion.

Jigsaw

This jigsaw was introduced in 1933 for faster sheet metal working in the automotive industry and in aircraft constructions. In 1927 electric handsaws began to be built for the timber industry.

Workstations in the design office

FEIN-Zwerg (the ‘Dwarf’)

This drill gained a patent for its housing: made of plastic, it serves as insulation. The idea of constructing the housing out of two halves, divided lengthwise, made possible what today we take for granted: the efficient, clearly arranged assembly of the tool’s inner workings in one of the two half-shells.

Anniversary celebrations

Celebrating 100 years of FEIN and 50 years of the training workshop with Joy Fleming, Liederhalle Stuttgart

Plaster cast saw

This saw was patented as a circular saw with an angular oscillating saw blade. It was used primarily in orthopaedics for cutting plaster casts. The crescent pattern of the oscillating rotation cut through the hard cast without damaging the patient’s skin. The plaster cast saw was equipped with a more powerful gearbox to upgrade it to a chassis saw. The plaster cast saw formed the basis of FEIN's range of sophisticated oscillating power tools.

Milling machine for underwater pipes

Oscillating cutting tool

FEIN worked in close partnership with the automotive industry to develop the chassis saw into an application solution for vehicles: There was no electric tool that could remove panes of glass bonded in place with silicone – until the problem was solved by the oscillating cutting tool, now fitted with specially shaped blades. The tool was continually developed and improved and is now known as the FEIN Super Cut Automotive; its main task is removing panes of window glass.

FEIN grinder

The universal FEIN grinder allowed users to grind workpieces that previously could only be machined by hand. The grinding disc, in the shape of a spherical triangle, and the rotary-oscillating motion achieve optimum grinding results even in previously inaccessible areas. Meanwhile the Fein grinder has developed and evolved far beyond its original function to become the FEIN MultiMaster, which performs a wide range of professional tasks: sawing, sanding, scraping, separating, rasping, polishing and cutting.

Advertisement for the new FEIN grinder

Safety angle grinder

The innovative FEIN technology used in the safety angle grinder is much safer for the user and saves a lot of time. When the angle grinder is switched off, the grinding disc is braked to a stop within 3 seconds – instead of the usual shut-off time of 20 seconds. QuickIN, the quick-attachment system developed specially for the safety angle grinder, allows the user to change discs without the need for tools.

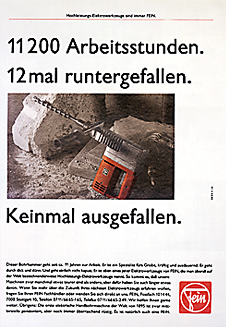

Hammer drill advert

Acquisition of Grit A/S: GRIT by FEIN

Developing solutions to metal machining problems - this is one of FEIN's core competencies. The GRIT by FEIN belt grinding system features many solutions.

EVO

A completely new operating concept, FEIN TipStart, is the key to the outstanding ergonomic quality, working safety and indestructibility of the improved safety angle grinder. The traditional switch is replaced by four completely dustproof and ergonomically positioned switchpads. Maintaining gentle pressure on one of the four switchpads will continue machine operations; releasing it will cause the machine to switch off immediately. The FEIN EVO offers optimum comfort grip.

FEIN MultiMaster

In January 2007 FEIN launched the latest generation of the FEIN MultiMaster with the QuickIN tool clamping system. This system significantly reduces the time required to change tools – a particular benefit in applications and renovation jobs where frequent tool changes are required. This multipurpose system for interior work and renovation is the repository of over 110 years of experience with power tools and more than 40 years of experience in oscillation technology.

Lithium-ion battery technology

FEIN presents not one, but two new products featuring lithium-ion battery technology. The battery-powered FEIN SuperCut: the world's most powerful renovation system and the battery-powered FEIN dry wall screw gun: up to 1,800 fittings with one battery charge.

FEIN KBH 25

The world’s first hand-held core drilling system for metal, the FEIN KBH 25 combines the advantages of high performance power drills and carbide-tipped core bits in a single system. The new drilling technology enables rapid work progress with considerably less effort and allows you to work up to five times faster when core drilling. Even in tight, difficult-to-reach locations, the FEIN KBH 25 plays off its strengths. A result of long experience and the enormous development edge that FEIN has as inventor of the power drill.

FEIN cordless drill/drivers

With 20 variants and a unique range of batteries, FEIN is underlining its expertise and experience in the construction of professional power tools.

FEIN Starlock oscillators (multi-tools)

Our new Starlock tool mounting once again reinforces our claim to be the number one oscillator supplier – and sees us setting new standards.

Cordless universal magnetic core drill

Small and powerful single-speed cordless universal magnetic core drill with forward/reverse running, MT2 tool mounting, permanent magnet and maximum functionality for mobile working on the construction site.